Image Source: www.madehow.com

How is Silica Cat Litter Made? Process: Step by Step

What is silica cat litter made from? Silica cat litter is primarily made from silicon dioxide, a common compound found in nature. Can I make silica cat litter at home? No, creating silica cat litter at home is not feasible due to the specialized industrial processes and equipment required. Who is involved in making silica cat litter? The process involves chemical manufacturers, specialized production facilities, and quality control specialists.

The world of cat litter has evolved significantly, moving from simple clay and sand to more advanced and effective options. Among these, silica gel cat litter stands out for its exceptional absorbency and odor control capabilities. But how exactly is this innovative product brought to life? The manufacturing of silica cat litter is a fascinating journey from raw material to the final product that graces our feline friends’ litter boxes. This in-depth exploration will guide you through the intricate steps involved in silica cat litter creation, unraveling the science and technology behind this popular pet care item.

The Core Component: Silicon Dioxide

At the heart of silica cat litter lies silicon dioxide (SiO₂), a naturally occurring compound. It’s the main ingredient in sand, quartz, and glass. However, the silicon dioxide used in cat litter isn’t just any sand. It undergoes a specific industrial process to create porous, highly absorbent silica gel. This porous structure is the key to silica cat litter’s effectiveness.

The journey begins with selecting high-quality raw materials for silica cat litter. These typically include:

- Sodium silicate: This is a soluble silicate salt that serves as the primary precursor. It’s often derived from quartz sand and sodium carbonate.

- Sulfuric acid: This strong acid is crucial for the chemical reaction that forms silica gel.

- Water: Essential for the reaction and washing process.

The Silica Gel Cat Litter Production Process: A Detailed Breakdown

The silica gel cat litter production is a multi-stage chemical and physical transformation. It’s a carefully controlled process to ensure the final product has the desired properties of absorbency, particle size, and safety.

Step 1: Sodium Silicate Solution Preparation

The process starts with the preparation of a sodium silicate solution. Sodium silicate, also known as water glass, is typically supplied as a viscous liquid. It’s carefully diluted with water to achieve a specific concentration. The purity of the sodium silicate is critical, as impurities can affect the quality and absorbency of the final silica gel.

- Concentration Control: The ratio of sodium silicate to water is precisely measured. This concentration influences the gel’s structure and pore size during formation.

- Filtration: The sodium silicate solution may be filtered to remove any solid particles or impurities before proceeding to the next stage.

Step 2: Gelation – The Formation of Silica Gel

This is the most critical step in silica crystal cat litter process. Here, the sodium silicate solution reacts with an acid, typically sulfuric acid, in a controlled manner. This reaction causes the silicate ions to link together, forming a three-dimensional network that traps water within its structure. This process is called gelation.

- Acidification: Sulfuric acid is slowly added to the sodium silicate solution under constant stirring. The acid neutralizes the sodium silicate, causing it to precipitate out as silicic acid.

- Polymerization: The silicic acid molecules then link together (polymerize) to form a gel. This gel is essentially a solid network of silicon dioxide with a high internal surface area and numerous pores.

- pH Control: Maintaining the correct pH level is vital. Too rapid acidification or incorrect pH can lead to the formation of a weak gel or undesirable byproducts.

- Temperature Management: The temperature during gelation is also controlled to optimize the gel structure.

The Chemical Reaction Explained

The simplified chemical reaction is as follows:

Na₂SiO₃ (Sodium Silicate) + H₂SO₄ (Sulfuric Acid) → H₂SiO₃ (Silicic Acid) + Na₂SO₄ (Sodium Sulfate)

The silicic acid then undergoes polymerization:

n H₂SiO₃ → (SiO₂)n · xH₂O (Silica Gel)

The byproduct, sodium sulfate, is a salt that needs to be separated from the silica gel.

Step 3: Aging the Gel

After the initial gelation, the gel is often allowed to “age” or “cure” for a period. This aging process allows the silica gel network to strengthen and stabilize. During aging, the gel structure can rearrange, and some water can be squeezed out, a process known as syneresis.

- Structural Stabilization: Aging helps to create a more robust and uniform porous structure within the silica gel.

- Syneresis: This phase can also help in removing some of the free water, making the subsequent drying process more efficient.

Step 4: Washing and Neutralization

The gel at this stage contains residual chemicals, primarily sodium sulfate, and excess acid. These need to be thoroughly removed to ensure the safety and performance of the cat litter.

- Washing: The gel is washed multiple times with clean water. This is a crucial step to remove soluble impurities like sodium sulfate. Large-scale production facilities use sophisticated washing systems, often involving multiple stages of rinsing and dewatering.

- Neutralization: If any residual acidity remains, a mild alkaline solution might be used for neutralization, followed by further washing to ensure a neutral pH. A neutral pH is important for both the cat’s comfort and to prevent degradation of the litter material.

Step 5: Drying

Once the silica gel is washed and free of impurities, it needs to be dried. This step removes the water from the gel’s pores and surface, leaving behind the highly absorbent silica gel beads. The drying process is carefully controlled to avoid damaging the delicate porous structure of the gel.

- Drying Methods: Various drying methods can be employed, including:

- Oven drying: The gel is placed in large ovens at controlled temperatures.

- Spray drying: A slurry of the gel is sprayed into a hot air stream, evaporating the water quickly. This can result in fine spherical particles.

- Fluidized bed drying: The gel particles are suspended in a stream of hot air, allowing for efficient and uniform drying.

The goal of the drying process is to achieve a specific moisture content in the silica gel, ensuring maximum absorbency.

Step 6: Size Reduction and Screening

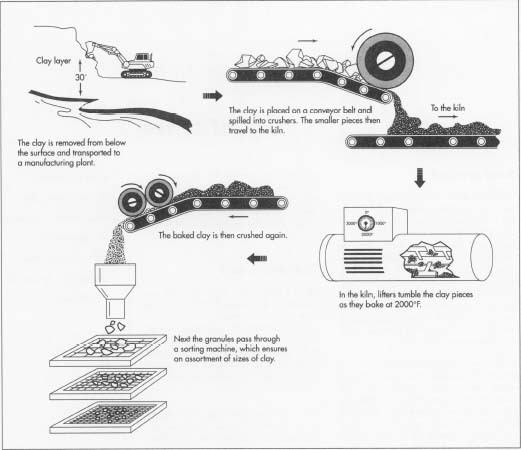

After drying, the silica gel may exist in various forms – clumps, irregular pieces, or fine powder, depending on the drying method. For cat litter, the material needs to be processed into uniform-sized particles, typically small beads or granules, to prevent tracking and ensure comfortable use for cats.

- Crushing and Milling: The dried silica gel is passed through crushers and mills to break it down into smaller particles.

- Screening/Sieving: The crushed material is then screened using different mesh sizes to separate particles into specific size ranges. This ensures a consistent granule size, which is important for both performance and aesthetics. Undersized particles (dust) and oversized particles are removed.

This stage is crucial for creating the characteristic silica beads cat litter making appearance and feel. The synthetic silica cat litter process relies heavily on precise particle size control.

Step 7: Optional Additives and Fragrances

While the basic silica gel is highly effective, some manufacturers may add optional components to enhance the product further.

- Odor Absorbers: Activated carbon or other odor-neutralizing agents can be incorporated to further boost odor control.

- Fragrances: Some silica cat litters are scented with mild fragrances to provide a pleasant aroma. These fragrances are typically pet-safe and designed to be subtle.

- Colorants: In rare cases, very small amounts of pet-safe colorants might be used, although most silica cat litter remains its natural translucent or white appearance.

These additives are typically mixed with the silica gel granules in a controlled blending process.

Step 8: Packaging

The final stage involves packaging the finished silica cat litter into bags or containers for distribution and sale. The packaging is designed to protect the product from moisture and damage during transit and storage.

- Moisture Protection: Silica gel can absorb moisture from the air, so packaging often includes measures to keep the product dry until it reaches the consumer.

- Bagging and Sealing: Automated bagging machines fill the product into pre-made bags, which are then sealed to maintain freshness and integrity.

This meticulous process, from the initial chemical reactions to the final packaging, is what defines the cat litter production techniques for silica-based products.

Understanding the Properties of Silica Cat Litter

The elaborate silica crystal cat litter process results in a product with unique and desirable characteristics for cat owners. The key properties stem directly from the structure of the silica gel.

| Property | Description | How Silica Gel Achieves It |

|---|---|---|

| High Absorbency | Silica gel can absorb several times its weight in liquid. | The extensive network of pores within the silica gel creates a massive internal surface area, allowing it to trap moisture efficiently. |

| Odor Control | It effectively locks away ammonia and other odor-causing compounds produced by cat urine. | The porous structure not only absorbs liquid but also traps odor molecules within its internal spaces, preventing them from escaping into the air. |

| Low Dust | High-quality silica cat litter produces very little dust, which is beneficial for both cats and humans with respiratory sensitivities. | The manufacturing process, particularly the screening and granulation steps, aims to produce smooth, rounded beads with minimal friable material. |

| Clumping Ability | Unlike clay litters, silica gel does not typically form hard clumps. Instead, it absorbs the liquid, keeping the surrounding granules dry. | The silica gel structure absorbs and holds liquid within its pores rather than binding it together into solid masses. |

| Lightweight | Compared to clay litters, silica cat litter is often lighter in weight, making it easier to carry and pour. | The porous nature of silica gel means it has a lower bulk density than solid clay particles. |

| Non-Clumping (for some types) | Some silica litters are designed to not clump, which some owners prefer for easier scooping as the urine stays contained within the dry granules. | This is a characteristic of how the silica gel absorbs and holds moisture without solidifying into clumps. |

Variations in Silica Cat Litter Production

While the core process for silica gel manufacturing for cat litter remains similar, there can be variations in the specific techniques and equipment used by different manufacturers. These variations can influence the final product’s texture, granule size, and overall performance.

- Particle Size and Shape: Some manufacturers focus on producing very fine silica gel beads, while others opt for larger granules. The shape can also vary from spherical to more irregular.

- Pore Size Distribution: The precise pore size and distribution within the silica gel can be manipulated during the gelation and drying stages. This can affect the rate of absorption and the types of odor molecules it can trap.

- Additives: As mentioned, the inclusion and type of additives can significantly differentiate products in the market.

- Manufacturing Scale: Production can range from smaller, specialized batches to massive industrial operations, each with its own set of efficiency and quality control measures.

Environmental Considerations and Safety

The production of silica cat litter is generally considered safe and environmentally responsible when conducted under proper industrial standards.

- Raw Material Sourcing: Silicon dioxide is abundant, but the extraction and processing of sodium silicate and sulfuric acid require careful management to minimize environmental impact.

- Waste Management: The primary byproduct is sodium sulfate, which can be a saleable commodity if it meets purity standards. Proper disposal of any chemical waste or wastewater is crucial.

- Energy Consumption: Drying and processing stages are energy-intensive. Manufacturers often look for energy-efficient technologies to reduce their carbon footprint.

- Pet Safety: The final silica gel product is inert and non-toxic. However, manufacturers must ensure no residual harmful chemicals remain after the washing and neutralization steps. The fine dust created during processing needs to be managed to prevent inhalation by workers and ultimately, by pets.

Frequently Asked Questions (FAQ)

Here are some common questions about silica cat litter and its production:

Q1: Is silica cat litter safe for my cat?

A1: Yes, high-quality silica cat litter is generally very safe for cats. The primary ingredient, silicon dioxide, is non-toxic. The manufacturing process ensures that any residual chemicals are removed. However, it’s always wise to observe your cat for any unusual behavior or sensitivities after switching litter types.

Q2: How often should I change silica cat litter?

A2: Silica cat litter typically lasts longer than traditional clay litters. While you should scoop solid waste daily, you may not need to replace the entire litter box contents as frequently. Depending on the number of cats and the litter’s capacity, a full change might be needed every 2-4 weeks, but the granular material will remain dry and odor-free for longer periods.

Q3: Why is silica cat litter more expensive than clay litter?

A3: The higher cost is due to the more complex manufacturing process, the specialized raw materials involved, and its superior performance in absorbency and odor control. The energy required for the intricate production steps also contributes to the price.

Q4: Does silica cat litter track outside the litter box?

A4: Some tracking can occur, especially with finer granules, but it is generally less than with clay litters. The larger, smoother silica beads tend to stay within the litter box more effectively.

Q5: Can silica cat litter be flushed down the toilet?

A5: It is generally not recommended to flush silica cat litter down the toilet. While it absorbs liquid, the silica granules themselves do not dissolve and can potentially cause clogs in plumbing systems or septic tanks. Always dispose of used cat litter in accordance with local waste disposal guidelines.

Q6: What is the difference between silica gel cat litter and silica sand cat litter?

A6: While both involve silicon dioxide, “silica gel cat litter” refers to the highly porous, manufactured gel product. “Silica sand cat litter” might refer to litters made from natural sand, which would have significantly lower absorbency and odor control compared to silica gel. The silica sand cat litter production methods are much simpler, but the end product is far less effective.

The journey of silica cat litter from basic chemical compounds to a highly effective pet product is a testament to modern manufacturing and material science. By following these detailed steps, manufacturers create a product that offers significant benefits to cat owners, making pet care easier and more hygienic. The intricate silica cat litter creation process ensures that the product performs exceptionally well in absorbing moisture and controlling odors, contributing to a cleaner and fresher home environment.